Breaking the Rectangular Mold in Liquid Packaging

In the competitive landscape of Fast-Moving Consumer Goods (FMCG), retail shelves are dominated by standard rectangular stand-up pouches. While efficient, the uniformity of traditional rectangular packaging can make it difficult for a new or premium product to capture consumer attention. For marketing managers and brand owners, the challenge is not just containment, but differentiation.

Custom shaped spout pouches—manufactured using precision die-cut technology—offer a powerful solution. By moving away from standard geometries, brands can create packaging that physically mimics the product flavor (e.g., a strawberry-shaped juice pouch) or enhances ergonomics (e.g., a contoured grip for automotive fluids). This guide explores the strategic advantages, technical implications, and manufacturing considerations of adopting shaped liquid packaging.

The Strategic Value of Die-Cut Shapes

Shaped pouches are not merely an aesthetic choice; they serve specific functional and psychological roles in the buyer’s journey.

1. Visual Disruption and Shelf Appeal

The human eye is trained to scan patterns. A unique silhouette breaks the visual monotony of a shelf lined with rectangular cartons and bags. A custom shape acts as a silent salesman, communicating the product’s identity before the consumer reads the label. For example, a pouch shaped like a bottle preserves the brand equity of rigid packaging while offering the cost and sustainability benefits of flexible packaging.

2. Ergonomics and Usability

Die-cutting allows for functional design improvements. Standard pouches can be difficult to grip when wet or full. A shaped pouch can incorporate:

- Waisted profiles: Narrower centers that fit comfortably in the hand.

- Dual chambers: Separating two ingredients until consumption (requires complex sealing).

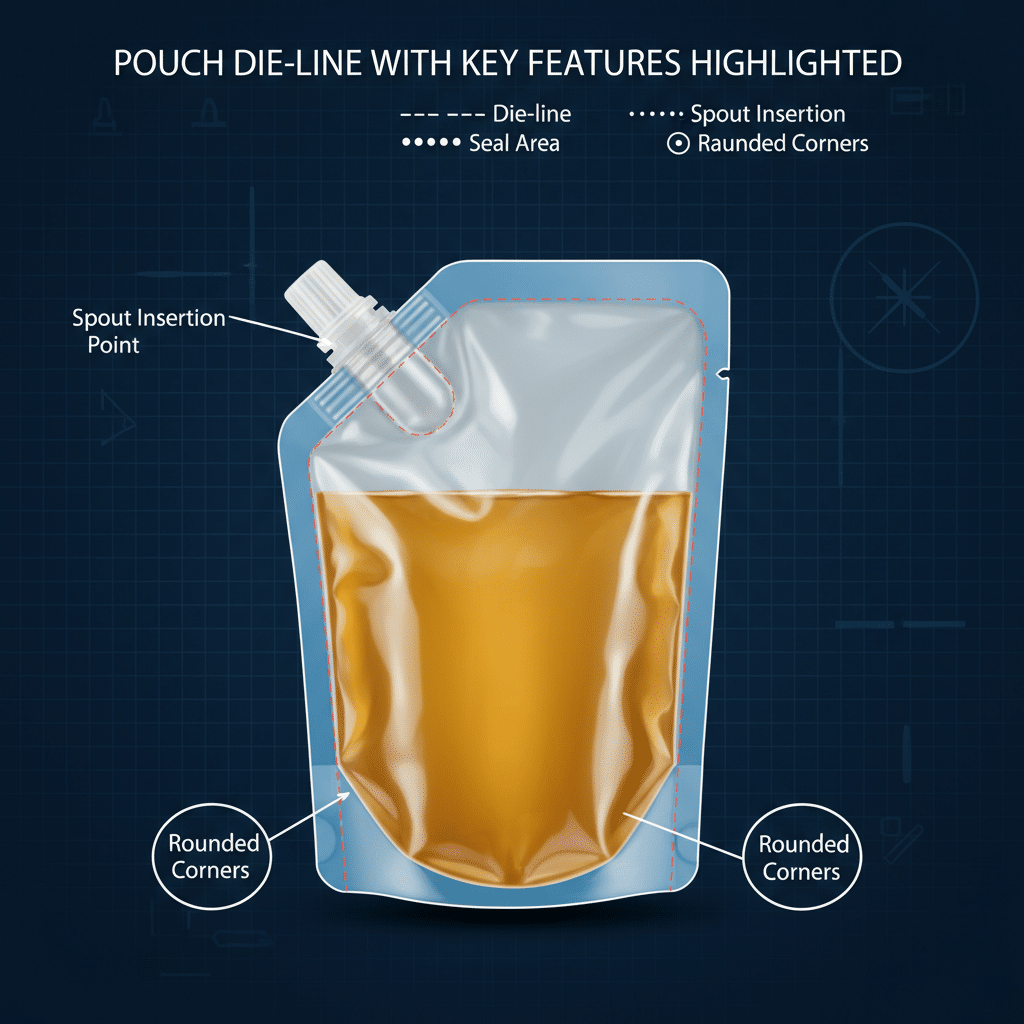

- Rounded corners: Mandatory for safety, particularly in baby food applications, but also an aesthetic smoother.

3. Brand Storytelling

For children’s products, shapes are critical. A pouch shaped like an animal or a fruit creates an immediate emotional connection with the target demographic. For industrial products, technical, angular shapes can convey strength and precision.

Technical Considerations for Shaped Pouches

Transitioning from a standard pouch to a shaped format involves specific engineering challenges. Procurement teams and engineers must align on the following specifications to ensure manufacturability.

Volume vs. Dimensions

Calculating the volume of a shaped pouch is more complex than a rectangular one. A “waisted” design reduces the internal volume. Therefore, the overall dimensions (width x height) usually need to increase to hold the same net weight as a rectangular counterpart. We recommend prototyping to verify fill volume before mass production.

Spout Placement and Stability

The shape dictates where the spout can be inserted—typically top-center or top-corner. However, the shape must also support the spout during the filling process. If the top of the pouch is too narrow or irregular, it may not accommodate the spout sealing jaws effectively. Furthermore, the bottom gusset design is crucial; a shaped pouch must still stand upright on the shelf without tipping over.

Material Stiffness

Complex shapes require materials with sufficient structural integrity to maintain the contour when the pouch is empty or partially full. Standard PET/PE structures are common, but thicker laminates or added nylon (OPA) layers may be required to prevent the “flopping” of intricate die-cut edges.

Manufacturing and Cost Implications

Understanding the OEM manufacturing process helps in budgeting and timeline planning.

Tooling Costs

Unlike standard bags, shaped pouches require custom die-cut molds. This is a one-time tooling fee paid upfront. The complexity of the shape influences the cost of the mold. Brands should ensure their design is finalized before mold creation to avoid re-tooling expenses.

Production Speed and Waste

Die-cutting is a mechanical process that stamps the shape out of the film web. Irregular shapes often result in higher “skeleton waste” (the film trimmed away) compared to rectangular pouches. Additionally, running shaped pouches on filling lines may require slower speeds or custom pucks/rails to transport the pouches, depending on the filling equipment used by the co-packer.

Buying Guide: Ordering Custom Shaped Pouches

When requesting a quote for shaped spout pouches, consider the following parameters to ensure accurate pricing and lead times.

1. Minimum Order Quantity (MOQ)

Due to the setup time and specific tooling required, MOQs for shaped pouches are generally higher than standard stock pouches. Expect starting MOQs in the range of 10,000 to 30,000 units, depending on the size and material structure.

2. Artwork and Die Lines

You must provide a vector-based die line (cut line) along with your artwork. If you do not have a die line, our engineering team can assist in creating one based on your concept sketches, ensuring the geometry is viable for production.

3. Prototyping

Before committing to a full production run, request a digital print sample or a handmade mockup. This allows you to test the physical feel, the pourability, and the shelf stability of the shape.

Frequently Asked Questions

Can any shape be manufactured as a spout pouch?

Most shapes are possible, but there are limitations. Extremely sharp angles (less than 90 degrees) can create weak points in the seal or trap product. Curves should be smooth, and the bottom gusset area must remain relatively standard to ensure the pouch stands.

Are shaped pouches recyclable?

Yes, shaped pouches can be made from mono-material structures (e.g., PE/PE) that are recyclable. However, the recyclability depends on the material chosen, not the shape itself.

How does the shape affect the spout insertion?

The area surrounding the spout must be flat and wide enough for the heat-sealing equipment to attach the spout. Designs with very narrow necks may need adjustment to accommodate standard spout diameters (8.6mm, 10mm, etc.).

Is the lead time longer for shaped pouches?

Yes, typically by 1–2 weeks for the initial order to allow for the fabrication of the custom die-cut mold. Repeat orders generally follow standard lead times.

Conclusion

Custom shaped spout pouches offer a high-impact way to differentiate your brand in a crowded market. While they require careful planning regarding volume, tooling, and design, the payoff in shelf visibility and consumer engagement is significant. By working closely with an experienced OEM partner, you can optimize your design for both manufacturability and marketing impact.

Ready to design your custom packaging?