For manufacturers of liquid foods, beverages, and sensitive chemical products, shelf life is not just a quality metric—it is a commercial imperative. The ability to maintain product integrity over months of storage and transport determines whether a brand can expand into export markets or must remain local.

While various flexible packaging options exist, aluminum foil spout pouches remain the gold standard for high-barrier protection. Unlike standard plastic laminates or metalized films, a true aluminum foil layer provides a near-absolute barrier against the three primary enemies of product stability: oxygen, moisture, and light.

This guide details the technical advantages of aluminum foil laminates, the structure of these high-performance materials, and why they are essential for brands targeting long expiration dates and international distribution.

The Technical Necessity of High-Barrier Packaging

Sensitive formulations—such as baby food, fruit purees, dairy-based sauces, and pharmaceutical liquids—degrade rapidly when exposed to environmental factors. Choosing the right packaging material is an engineering decision based on the required Oxygen Transmission Rate (OTR) and Water Vapor Transmission Rate (WVTR).

1. Oxygen Barrier (OTR)

Oxidation is the primary cause of food spoilage, leading to rancidity in fats, discoloration in pigments, and the breakdown of vitamins (particularly Vitamin C). Standard plastics like polyethylene (PE) or polypropylene (PP) are porous to gas at a microscopic level. By incorporating a layer of aluminum foil (typically 7 to 9 microns thick) into the laminate structure, the OTR is reduced to effectively zero. This prevents oxidation, preserving flavor and nutritional value without heavy reliance on artificial preservatives.

2. Moisture Barrier (WVTR)

Moisture control works two ways. For liquid products, the goal is to prevent water loss (evaporation), which alters viscosity and texture. For hygroscopic powders or dry goods, the goal is to keep moisture out. Aluminum foil offers the lowest WVTR of any flexible packaging material, ensuring the product inside remains at the precise moisture content intended at the time of filling.

3. UV and Light Protection

Photo-oxidation degrades light-sensitive ingredients, causing off-flavors (often described as “skunky” in beverages) and nutrient loss. While opaque plastic films block visible light, they may still allow UV penetration. Aluminum foil provides a complete block against all light spectrums, making it the only viable flexible option for highly photosensitive products.

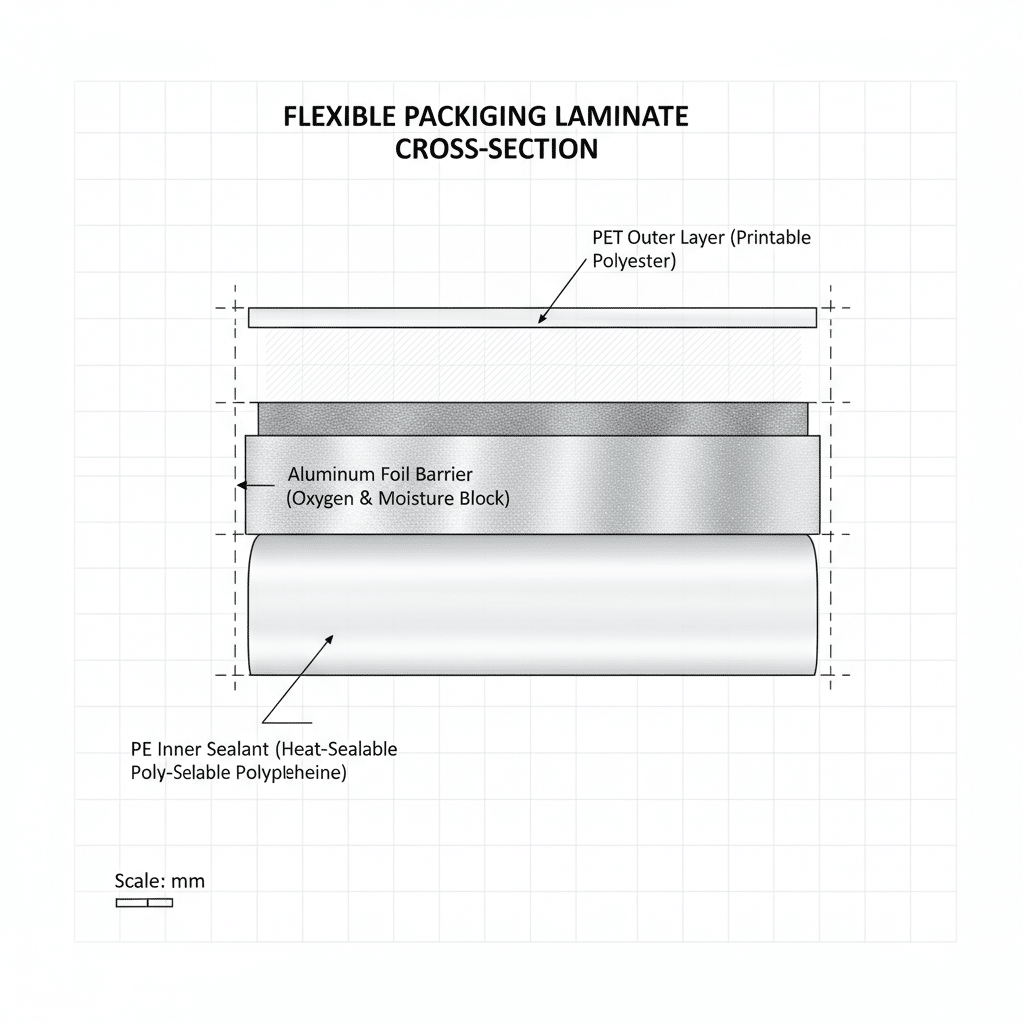

Anatomy of a Foil Spout Pouch

An aluminum foil spout pouch is never made of foil alone; pure foil is too fragile and cannot be heat-sealed. Instead, it is a multi-layer laminate engineered for specific performance characteristics. A typical high-barrier structure includes 3 to 4 layers:

- Outer Layer (PET or OPP): Provides a smooth surface for high-quality rotogravure printing and protects the barrier layer from physical scratches.

- Middle Layer (AL – Aluminum Foil): The functional barrier layer that blocks light, oxygen, and moisture.

- Reinforcement Layer (NY – Nylon/OPA): Often added in larger pouches (e.g., 1L or above) or drop-test sensitive applications to add puncture resistance and tensile strength, protecting the foil from cracking (pinholing).

- Inner Layer (PE, CPP, or RCPP): The sealant layer. This food-grade plastic melts to form the seal and bonds the spout to the pouch body. Retort CPP (RCPP) is used if the product requires sterilization at high temperatures (121°C+).

Aluminum Foil vs. Metalized PET (VMPET)

A common point of confusion for buyers is the difference between Aluminum Foil (AL) and Metalized PET (VMPET). While both look silver and metallic, their performance differs significantly.

| Feature | Aluminum Foil (AL) | Metalized PET (VMPET) |

|---|---|---|

| Structure | A solid sheet of thinly rolled aluminum alloy. | Plastic film sprayed with aluminum vapor. |

| Barrier Level | Extremely High (Near Zero OTR/WVTR). | Moderate to High. |

| Light Blocking | 100% Opaque. | <99% (Strong light can penetrate). |

| Flexibility | Has “dead fold” characteristics (stays folded). | Flexible, springs back. |

| Best For | Retort products, baby food, long shelf life (12-24 months), exports. | Snacks, dried goods, short shelf life liquids, cost-sensitive items. |

For products requiring a shelf life exceeding 12 months or those undergoing thermal processing (retort), Aluminum Foil is the mandatory choice.

Strategic Advantages for Export and Logistics

Using aluminum foil spout pouches offers distinct logistical advantages over rigid packaging (glass bottles, metal cans) for export markets.

Weight and Space Reduction

Rigid packaging is heavy and transports “air” due to its shape. Spout pouches are flat prior to filling and lightweight after filling. This significantly reduces freight costs and carbon footprint during international shipping.

Durability in Transit

Glass breaks; cans dent. A multi-layer foil laminate is flexible and durable. When reinforced with Nylon (NY), these pouches withstand the vibration, pressure changes, and rough handling associated with sea freight and overland distribution.

Cost-Efficiency

While foil laminates are more expensive than clear plastics, they are generally cheaper than rigid containers (glass/metal) when factoring in caps, labels, and secondary packaging requirements.

Buying Guide: Sourcing Foil Spout Pouches

When sourcing these pouches from an OEM manufacturer, consider the following specifications to ensure the packaging meets your product’s needs:

- Retort Requirements: If your product is hot-filled and then sterilized in the pouch (retort), you must specify this. Standard laminates will delaminate under retort conditions.

- Acid Resistance: High-acid products (like tomato paste or fruit juice) can corrode standard foil adhesives. Ensure the manufacturer uses acid-resistant bonding agents.

- Spout Fitment: The spout material (usually PE or PP) must match the inner sealant layer of the pouch for a hermetic seal.

- MOQ (Minimum Order Quantity): Custom-printed foil pouches typically require rotogravure printing. This process involves creating cylinders for each color, usually setting MOQs between 10,000 to 30,000 units depending on pouch size.

Frequently Asked Questions

Can aluminum foil spout pouches be microwaved?

No. Because they contain a metal layer, aluminum foil pouches cannot be microwaved. If microwave convenience is required, high-barrier transparent coatings (like ALOX or SIOX) are recommended instead.

Are these pouches recyclable?

Standard foil laminates are mixed-material structures (Plastic + Aluminum), which makes them difficult to recycle in standard streams. However, they reduce overall waste volume compared to rigid packaging. For sustainable options, ask about mono-material pouches, though note that they currently offer lower barrier properties than foil.

What is the typical lead time for custom foil pouches?

Once artwork is approved and cylinders are engraved, production typically takes 3 to 4 weeks, plus shipping time. It is advisable to plan inventory 2–3 months in advance for international orders.

Can I see the product inside?

No, aluminum foil is opaque. If product visibility is a marketing requirement, you may need to compromise on shelf life or use a windowed pouch (which removes the foil from the window area, reducing barrier performance) or switch to high-barrier clear laminates.

Conclusion

Aluminum foil spout pouches represent the intersection of convenience and preservation. For B2B buyers and brand owners, they offer a reliable method to extend shelf life, reduce spoilage claims, and open new markets without the logistical heavy lifting of rigid containers.

Ready to secure your product’s quality?

Contact us today to discuss your specific barrier requirements, request material data sheets, or get a sample of our high-performance foil pouches.