For infant nutrition brands, packaging safety is not just a regulatory requirement—it is the primary driver of consumer trust. The shift from traditional glass jars to flexible packaging has transformed the baby food aisle, with baby food spout pouches becoming the preferred format for modern parents. This transition is driven by two critical factors: the uncompromised safety of materials and the unparalleled convenience of on-the-go feeding.

However, sourcing packaging for vulnerable demographics like infants requires strict adherence to manufacturing standards. From BPA-free packaging materials to anti-choke cap designs, every component must be vetted for compliance and functionality. This guide explores the technical and practical reasons why brands are standardizing on spout pouches and what procurement teams need to know when selecting a spout bag manufacturer.

The Anatomy of a Safe Baby Food Pouch

Unlike general flexible packaging, pouches designed for infant nutrition must withstand rigorous processing conditions while maintaining chemical inertness. The safety of the pouch begins with its material structure.

Material Structure and Barrier Properties

Baby food products are highly sensitive to oxygen, moisture, and light, which can degrade nutrients and spoil the product. To combat this without using preservatives, manufacturers use multi-layer laminated films. A typical structure for a high-quality baby food pouch includes:

- PET (Polyethylene Terephthalate): The outer layer that provides structural integrity and a printable surface.

- AL (Aluminum Foil) or NY (Nylon): The barrier layer. Aluminum offers the highest barrier against light and oxygen, essential for extended shelf life. Nylon is often used for its puncture resistance and flexibility.

- RCPP (Retort Cast Polypropylene) or PE (Polyethylene): The inner sealing layer. For baby foods that require sterilization after filling (retort processing), RCPP is mandatory as it withstands high temperatures (typically 121°C to 135°C) without delaminating or leaching chemicals.

BPA-Free and Food Grade Compliance

The most critical specification for any infant nutrition packaging is that it must be free from Bisphenol A (BPA) and phthalates. Professional manufacturers ensure that all adhesives, films, and spouts are certified food-grade. When sourcing these pouches, brands should request compliance documentation (such as FDA or EU food contact compliance) to verify that the inner layers interacting with the food are chemically safe.

The Critical Role of Anti-Choke Caps

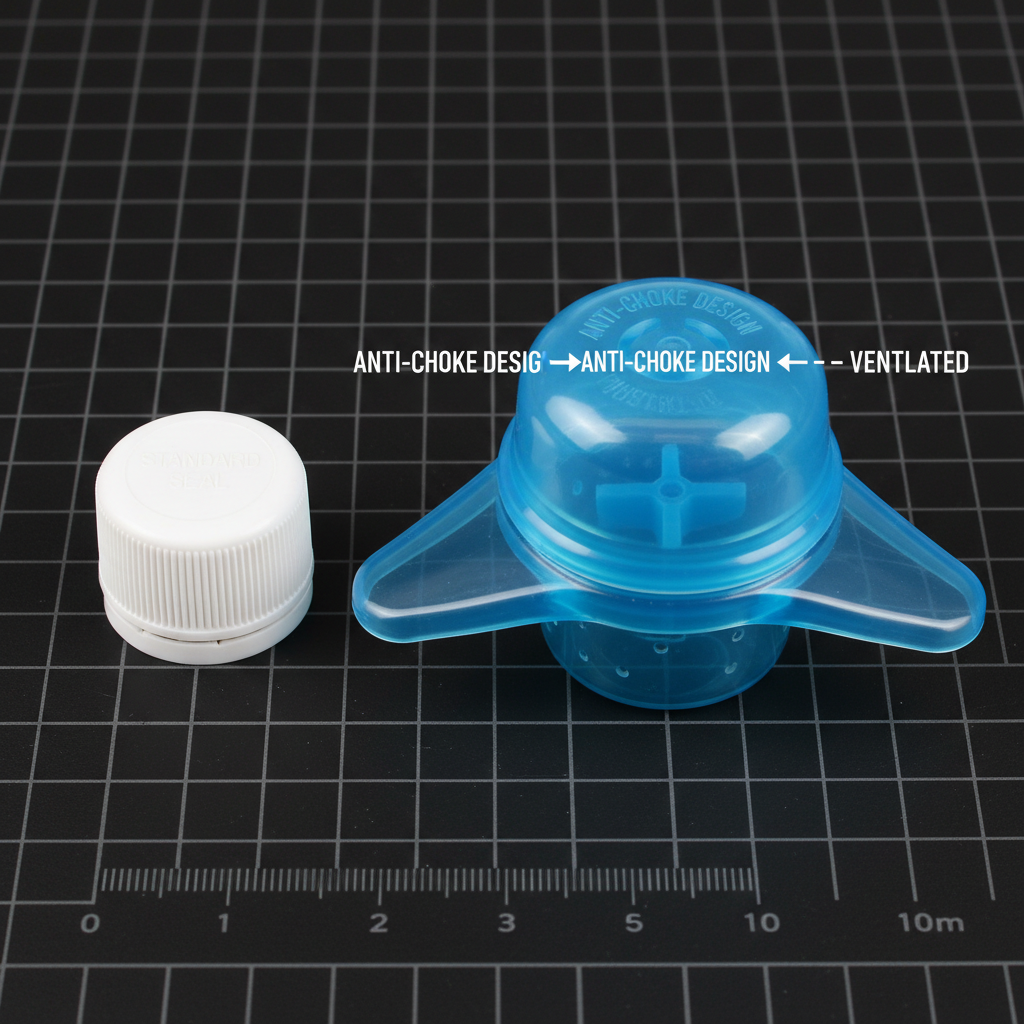

One of the defining features of baby food pouches is the closure system. Standard screw caps used for beverages are often too small and pose a choking hazard if a child accidentally swallows them. To mitigate this risk, the industry has adopted child-safe caps, often referred to as “anti-choke” or “swallow-proof” caps.

Technical Specifications for Safety

Anti-choke caps are significantly larger than standard spouts, typically measuring over 30mm in diameter (often 33mm). Their design usually features:

- Large Diameter: Physically too large to pass through a child’s esophagus.

- Ventilation Slots: Some designs include integrated holes or shapes that allow air passage even if the cap is placed in the mouth, although size is the primary deterrent.

- Easy-Grip Wings: The “helicopter” or winged shape allows parents to open the pouch easily while preventing the child from swallowing the cap.

When working with a manufacturer, it is essential to specify the cap diameter and request samples to test the opening torque, ensuring it is secure enough to prevent leaks but accessible for adults.

Convenience: The Driver of Market Growth

While safety is the baseline, convenience is what sells the product. Flexible food packaging offers distinct advantages over glass and rigid plastic:

- Portability: Pouches are lightweight and shatterproof, making them safe for travel and diaper bags.

- Self-Feeding: The spout design allows toddlers to feed themselves, fostering independence and developing fine motor skills.

- Resealability: If the child does not finish the portion, the cap can be screwed back on, and the pouch can be refrigerated for later consumption (within safe timeframes).

- Evacuation Rate: Flexible pouches allow users to squeeze out nearly 99% of the product, reducing food waste compared to jars where product gets stuck under the rim.

Manufacturing Considerations for Brands

Transitioning to or launching a new line of baby food pouches involves several manufacturing decisions. Understanding the capabilities of your OEM partner is vital.

Retort vs. Hot Fill vs. Cold Fill

The filling process dictates the pouch specifications:

| Process | Description | Pouch Requirement |

|---|---|---|

| Retort | Product is filled, sealed, and then sterilized in an autoclave at high heat. | Requires high-performance Retort CPP (RCPP) layers and specialized adhesives to prevent delamination under heat. |

| Hot Fill | Product is heated (e.g., 85°C-90°C), filled, and then cooled. | Requires materials that can withstand moderate heat without warping. Standard PE or CPP is often sufficient. |

| Cold Fill / HPP | Filled at ambient/cold temps. May use High Pressure Processing (HPP) for sterilization. | Requires strong seals to withstand high pressure. Aluminum foil is generally not compatible with HPP; clear barrier films are used instead. |

Printing and Customization

Baby food packaging relies heavily on shelf appeal. Rotogravure printing is the standard for high-volume orders, offering up to 10 colors with photo-realistic quality. This allows brands to use vibrant colors and clear nutritional information, which is crucial for parents making quick decisions. For smaller runs or test markets, digital printing is an emerging option that eliminates plate costs.

Buying Guide: Sourcing Baby Food Pouches

When approaching a supplier, having a clear set of requirements expedites the quoting process. Consider the following factors:

1. Minimum Order Quantities (MOQ)

Due to the complex setup of rotogravure printing and pouch converting, MOQs for custom baby food pouches are typically higher than standard bags, often starting at 10,000 to 30,000 units per SKU. Discuss MOQ early to ensure alignment with your production volume.

2. Spout Location and Type

While top-center spouts are standard for baby food to facilitate squeezing, corner spouts are also available. Ensure the spout diameter (usually 8.6mm or 10mm internal bore) matches your filling equipment nozzles.

3. Quality Assurance

Ask your manufacturer about their leak testing protocols. Reputable suppliers use pressure decay testing and vacuum chambers to ensure seal integrity. For baby food, a zero-tolerance policy for leakage is standard.

Frequently Asked Questions (FAQs)

Are aluminum foil pouches safe for baby food?

Yes. The aluminum layer is sandwiched between plastic layers and never comes into direct contact with the food. It serves as an excellent barrier against light and oxygen to preserve nutrients.

Can baby food pouches be microwaved?

Generally, no. If the pouch contains an aluminum foil layer, it cannot be microwaved. Even for non-foil pouches, it is usually recommended to heat the food in a separate bowl to ensure even heating and prevent hot spots that could burn the child.

What is the lead time for custom printed pouches?

Typical lead times for custom rotogravure printed pouches range from 3 to 5 weeks after artwork approval, depending on the complexity and quantity. Shipping times should be calculated on top of production time.

Do you offer recyclable options for baby food packaging?

Yes, mono-material (PE/PE) pouches are becoming available. These are designed to be recyclable, though they may have lower barrier properties compared to foil-based structures. Discuss shelf-life requirements with your manufacturer before choosing recyclable materials.

Conclusion

Choosing the right packaging for infant nutrition is a balance of rigorous safety standards and consumer convenience. Baby food spout pouches with BPA-free packaging materials and child-safe caps provide the ideal solution for modern brands. By understanding the technical nuances of barrier films and filling processes, procurement teams can partner effectively with manufacturers to deliver a product that parents trust.

Ready to develop your custom baby food packaging? Request a quote today or ask for a sample kit to evaluate our material quality and cap safety features firsthand.