Selecting the right packaging material for liquid and semi-liquid products is often a tug-of-war between marketing goals and technical preservation requirements. For brand owners and procurement managers, the choice between transparent spout pouches and aluminum foil spout pouches determines not just the look of the product on the shelf, but its stability, shelf life, and supply chain viability.

At SpoutPouchOEM, we manufacture both high-barrier foil and high-clarity transparent pouches. We understand that while consumers love to see what they are buying, sensitive formulations often demand the absolute protection that only aluminum can provide. This guide explores the technical trade-offs, material specifications, and strategic considerations to help you make the right sourcing decision.

The Core Conflict: Visibility vs. Barrier Protection

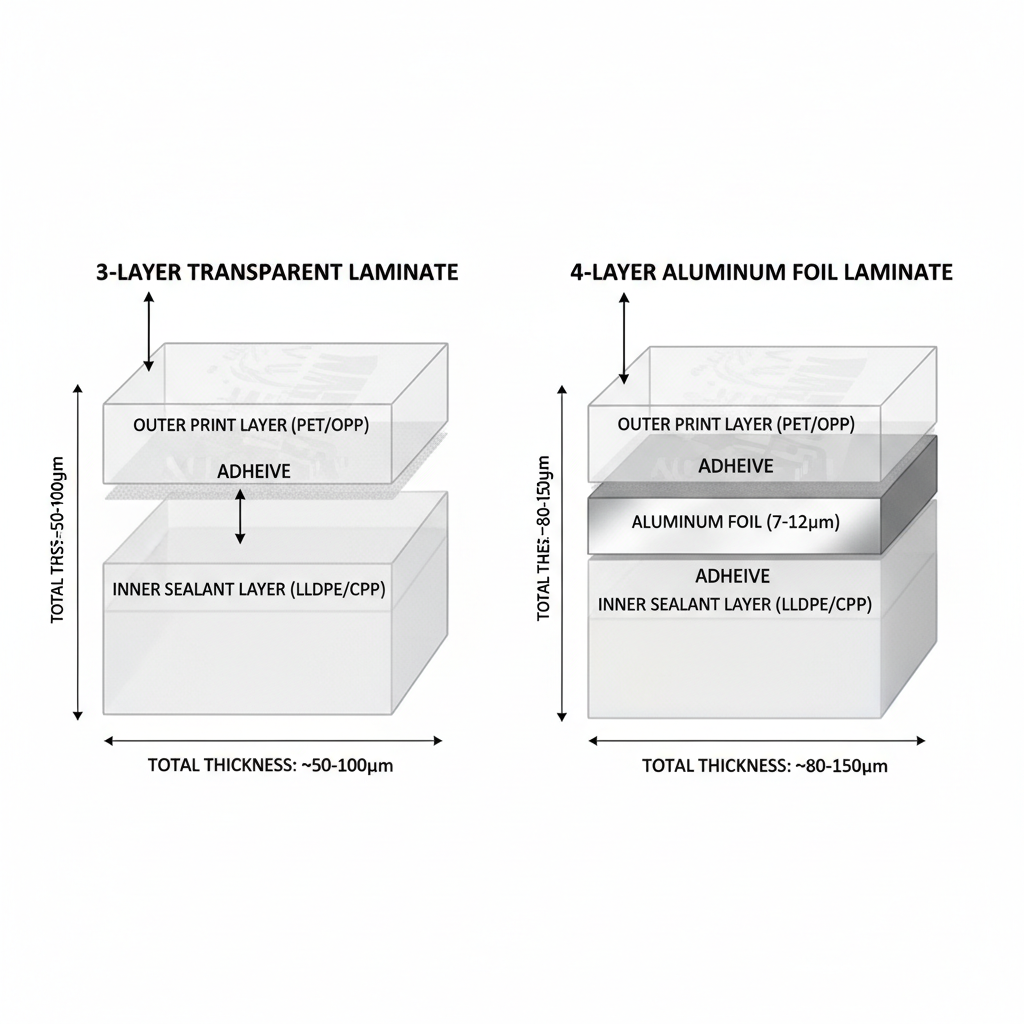

The primary distinction lies in the laminate structure. Flexible packaging is rarely a single layer; it is a lamination of films designed to perform specific roles (printability, strength, barrier, and sealing).

- Transparent Pouches: Typically use a structure like PET/NY/PE (Polyester/Nylon/Polyethylene). They rely on the plastic layers to provide a moderate barrier against oxygen and moisture while allowing full light transmission.

- Aluminum Foil Pouches: Typically use a structure like PET/AL/PE or PET/AL/NY/PE. The thin layer of aluminum foil creates a near-total barrier against light, oxygen, and moisture.

1. Transparent Spout Pouches: Building Consumer Trust

Transparent packaging is a powerful marketing tool. It leverages the psychology of “what you see is what you get.”

Pros:

- Product Visibility: Ideal for products with appealing colors or textures, such as fruit juices, honey, or colorful detergents. It reassures the consumer that the product is fresh and free of contaminants.

- Cost Efficiency: Generally, transparent laminates are slightly less expensive than high-grade aluminum laminates due to the raw material costs of foil.

- Microwavability: If your product needs to be heated in the pouch (e.g., certain sauces), transparent retort structures (using AlOx or SiOx coatings instead of metal) allow for microwave use, whereas standard foil does not.

Cons:

- Light Exposure: UV and visible light can degrade photosensitive ingredients (like Vitamin C in juices or fats in dairy), leading to oxidation, color changes, or spoilage.

- Lower Barrier Properties: While high-barrier transparent coatings (like EVOH) exist, they generally do not match the absolute zero transmission rates of aluminum foil for oxygen and moisture over long periods.

2. Aluminum Foil Spout Pouches: The Gold Standard for Shelf Life

When shelf stability is the priority, especially for export markets or long supply chains, aluminum foil is the material of choice.

Pros:

- Superior Barrier: Aluminum foil provides the highest level of protection against oxygen, moisture, and UV light. This is critical for preventing oxidation in baby food, pharmaceuticals, and chemical products.

- Extended Shelf Life: Products packaged in foil pouches typically maintain their quality significantly longer than those in transparent pouches, reducing waste and allowing for longer distribution timelines.

- Premium Feel: Metallic finishes (or matte finishes over foil) often signal a premium quality product to buyers.

Cons:

- Opacity: Consumers cannot check the product condition before purchase. Brands must rely entirely on high-quality printing and imagery to convey the product contents.

- Rigidity and Creasing: Foil laminates can be more prone to visible creasing (flex-cracking) if not handled correctly during logistics, though proper material engineering mitigates this.

Technical Comparison: OTR and WVTR

For engineers and QA managers, the decision often comes down to the transmission rates. These figures represent how much oxygen or water vapor passes through the packaging material over time.

| Feature | Transparent Pouch (Standard) | Aluminum Foil Pouch |

|---|---|---|

| Structure Example | PET / NY / PE | PET / AL / NY / PE |

| Oxygen Barrier (OTR) | Moderate (needs EVOH for high barrier) | Excellent (Near Zero) |

| Moisture Barrier (WVTR) | Good | Excellent (Near Zero) |

| Light Barrier | None (100% transmission) | 100% Blockage |

| Shelf Life Potential | Short to Medium (3–12 months) | Long (12–24+ months) |

Strategic Sourcing Guide: When to Choose Which?

As an OEM manufacturer, we recommend analyzing your product’s sensitivity and your supply chain reality before finalizing the specification.

Choose Transparent If:

- Visual Appeal is Key: Your product’s color or texture is a unique selling point (e.g., bright smoothies, particulate soaps).

- High Turnover: The product has a fast consumption rate and does not sit on shelves for more than 6–12 months.

- Cold Chain Distribution: If your product is refrigerated (HPP juices, fresh dairy), the cold temperature slows degradation, making the high barrier of foil less critical.

Choose Aluminum Foil If:

- Photosensitivity: Your ingredients degrade under light (e.g., natural oils, certain vitamins, baby food purees).

- Long Shelf Life Required: You need 18–24 months of stability at ambient temperatures.

- Aggressive Contents: Some chemical formulations or highly acidic products require the chemical resistance and robustness of a foil-based laminate structure.

- Retort Processing: While transparent retort pouches exist, foil is the standard for high-temperature sterilization (121°C+) to ensure absolute seal integrity and barrier performance post-retort.

Manufacturing and Customization Considerations

Switching between transparent and foil materials affects the manufacturing setup.

- Printing: Both materials support high-definition Rotogravure or Digital printing. However, with transparent pouches, you have the option of “window” printing—leaving a section clear so the product shows through. With foil, the entire surface is opaque, offering a metallic canvas for design.

- MOQ (Minimum Order Quantity): Generally, MOQs are determined by the amount of film required to run the machinery efficiently. Foil laminates are specialized; ensure you clarify MOQs for custom-printed foil structures, as they may differ slightly from standard clear films.

- Lead Times: Standard PET/PE films are often readily stocked. Specialized foil laminates or high-barrier transparent films (like AlOx PET) may have slightly longer procurement lead times depending on global supply.

Frequently Asked Questions (FAQs)

Can I get a transparent pouch with a high oxygen barrier?

Yes. We can use EVOH (Ethylene Vinyl Alcohol) or coated films (like AlOx or SiOx) to create a transparent pouch with barrier properties that approach those of foil. This is a premium option for brands that need visibility and shelf life.

Is aluminum foil packaging more expensive?

Typically, yes. The raw material cost of aluminum and the additional lamination steps often make foil pouches marginally more expensive than standard transparent pouches. However, the cost of product spoilage usually outweighs the packaging cost difference.

Which is better for recycling?

Standard multi-layer laminates (both foil and non-foil) can be challenging to recycle in traditional streams. However, the industry is moving toward mono-material structures (PE/PE) which are transparent and recyclable, though they offer lower barriers than foil. If sustainability is your priority, ask us about our recyclable spout pouch lines.

Secure Your Product’s Success

The choice between transparent and aluminum foil spout pouches is a balance of science and sales. Whether you need the shelf-popping clarity of a transparent window or the fortress-like protection of aluminum foil, SpoutPouchOEM has the capability to engineer the exact laminate structure your product requires.

Ready to test your packaging strategy? Contact our engineering team today to discuss your barrier requirements and request samples of both materials.