In the infant nutrition market, packaging does more than contain the product—it protects the most vulnerable consumers. For baby food brands, the transition from glass jars to flexible spout pouches has been driven by convenience, portability, and safety. However, sourcing the right baby food spout pouch requires a deep understanding of material science, sterilization processes, and mechanical safety features.

Parents today scrutinize every detail of a product, from ingredient lists to the plastic touching the food. As a brand owner or procurement manager, ensuring your packaging meets rigorous safety standards is not just a regulatory requirement; it is the foundation of brand trust. This guide explores the critical technical considerations for manufacturing safe, reliable, and market-ready baby food pouches.

Why Material Selection is Critical for Baby Food

Baby food packaging must withstand rigorous processing conditions while preventing chemical migration. Unlike standard beverage pouches, baby food pouches often undergo high-temperature sterilization (retort) to ensure shelf stability without preservatives. This demands a specialized laminated structure.

Retort Capabilities and Barrier Properties

Standard polyethylene pouches cannot survive the retort process (typically 121°C / 250°F for 30–60 minutes). If the wrong materials are used, the pouch will delaminate, melt, or leach chemicals. High-quality baby food pouches typically utilize a multi-layer structure designed for thermal resistance and high barrier protection:

- Outer Layer (PET or NY): Provides mechanical strength and a printable surface.

- Barrier Layer (AL or ALOx): Aluminum foil is the gold standard for blocking light, oxygen, and moisture, ensuring nutrients remain intact. Transparent high-barrier coatings (like ALOx) are an alternative if product visibility is required, though less common for shelf-stable purees.

- Inner Layer (RCPP – Retort Cast Polypropylene): The sealing layer must be food-grade RCPP, which withstands high heat without compromising the seal integrity.

Chemical Safety: BPA and Phthalate Free

Chemical migration is a primary concern for parents. It is imperative that all layers, adhesives, and spouts are certified BPA-free (Bisphenol A) and phthalate-free. Manufacturers must adhere to international food contact regulations (such as FDA or EU standards) to ensure no harmful substances migrate into the puree, especially during the heating phase of the retort process.

Spout and Cap Engineering: Preventing Choking Hazards

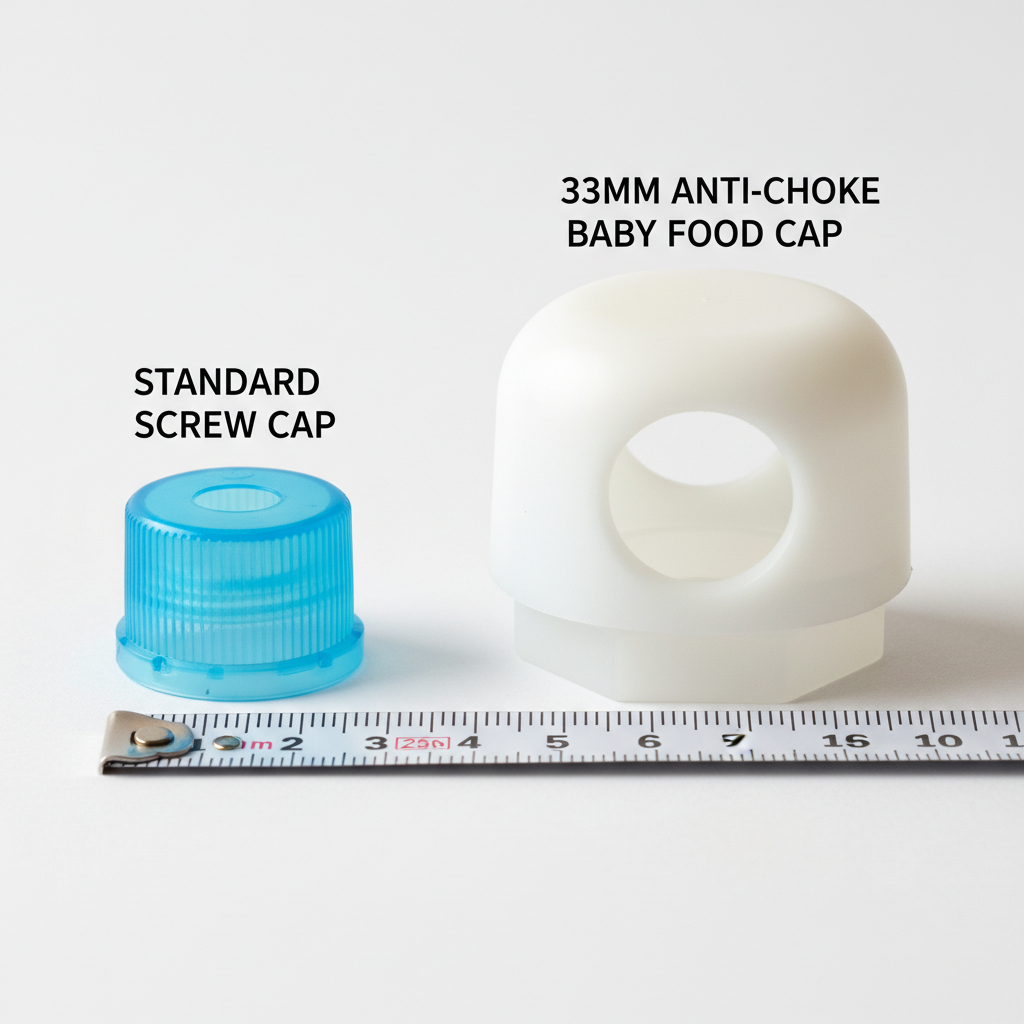

Beyond the film, the rigid components of the pouch—the spout and cap—pose specific mechanical safety challenges. The design must prevent choking hazards while remaining easy for parents to open.

The Anti-Choke Cap Standard

Standard small caps used for beverages are generally considered unsafe for baby products due to the risk of ingestion. The industry standard for baby food is the anti-choke cap (often 33mm in diameter or larger). These caps are designed to be too large for a child to swallow. Additionally, they often feature:

- Breathing holes: Some designs include integrated airways to allow airflow if the cap is accidentally lodged in a throat (though size is the primary deterrent).

- Tamper-evidence: A safety ring that breaks upon first opening provides visual assurance to the parent that the product is sterile and untouched.

Rounded Edges and Soft Corners

Flexible packaging should be safe to handle. Sharp corners on the pouch seal can scratch a child’s skin. Premium baby food pouches utilize rounded corner cutting during the converting process to ensure the package is soft and safe for little hands to hold.

Manufacturing and Quality Assurance Protocols

Producing spout pouches for infant nutrition requires stricter quality control than general industrial packaging. Defects such as micro-leaks can lead to spoilage and bacterial growth (e.g., mold), which can destroy a brand’s reputation overnight.

Burst and Pressure Testing

Pouches must withstand the pressure of the retort chamber, shipping logistics, and the squeeze of a toddler. Manufacturers should perform regular burst strength tests and compression tests to ensure the seals and spout welds do not fail under pressure.

Leak Detection

Automated manufacturing lines should include inline leak detection systems. However, random sampling for vacuum leak testing is also a standard QA procedure. This ensures that the hermetic seal is perfect, preventing oxygen ingress that causes spoilage.

Customization Options for Market Appeal

While safety is paramount, shelf appeal drives sales. Spout pouches offer excellent branding real estate.

- Rotogravure Printing: Ideal for high-volume runs, offering photo-realistic quality and vibrant colors that appeal to parents and children.

- Matte vs. Gloss Finish: A matte finish can give the pouch a premium, organic feel, while spot gloss can highlight logos or fruit imagery.

- Shaped Pouches: Die-cut shapes (e.g., fruit shapes or ergonomic curves) can make the product easier to hold and more visually distinct on the shelf.

Buying Guide: Sourcing Baby Food Pouches

When selecting a manufacturing partner for baby food packaging, procurement teams should evaluate the following criteria to ensure safety and supply chain reliability.

1. Minimum Order Quantity (MOQ)

Because baby food pouches require specific materials (retort-grade) and components (anti-choke caps), MOQs are often higher than standard pouches. Typical MOQs for rotogravure printed pouches start around 10,000 to 30,000 units per SKU, depending on the size and number of colors.

2. Lead Times

Production involves cylinder making, printing, laminating, curing (essential for food safety), pouch forming, and spout insertion. Expect lead times of 3–5 weeks for new orders. Rush orders are risky in this category due to the necessary curing time for adhesives to ensure no chemical migration.

3. Artwork and Prototyping

Ensure your manufacturer accepts standard AI or PDF design files. Requesting digital proofs or physical samples (even unprinted dummies) is crucial to verify the spout fit and pouch capacity before mass production.

Frequently Asked Questions

What is the difference between a standard spout pouch and a retort pouch?

A standard pouch is used for cold or ambient fill products (like juice or detergent). A retort pouch is constructed with specialized heat-resistant films and adhesives to withstand sterilization temperatures (121°C) without delaminating, making it suitable for shelf-stable baby food.

Are aluminum foil layers necessary for baby food?

Aluminum foil provides the highest barrier against oxygen and light, offering the longest shelf life (12–24 months). While transparent high-barrier options exist, foil remains the most reliable choice for sensitive baby purees.

How do I know the pouches are BPA-free?

Reputable manufacturers should provide material safety data sheets (MSDS) or compliance certificates confirming that all films and spouts are food-grade and free from Bisphenol A (BPA) and phthalates.

Can I get a custom spout color?

Yes, spouts and caps can be customized in various colors to match your branding. However, custom colors often require higher MOQs compared to standard white, clear, or orange caps.

Ready to secure safe, high-quality packaging for your baby food brand? Contact us today to discuss your specifications, request a quote, or get a sample of our retort-grade spout pouches.